Biogas Filters for the Enhancement Process

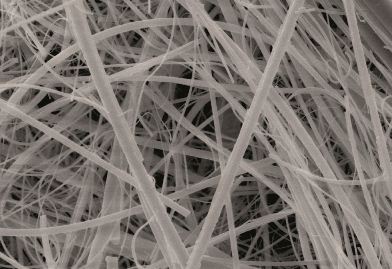

Do you need a biogas filter system? The biogas produced by the anaerobic digestion of organic waste can be converted into biomethane, this is called biogas upgrading. To help prevent further CO2 emissions, this 100% renewable energy can be used to replace fossil fuels. Biogas upgrade technology Various biogas upgrading technologies are available such as…