Borosilicate Glass Microfibre Filter Elements – what are they and why are they so special?

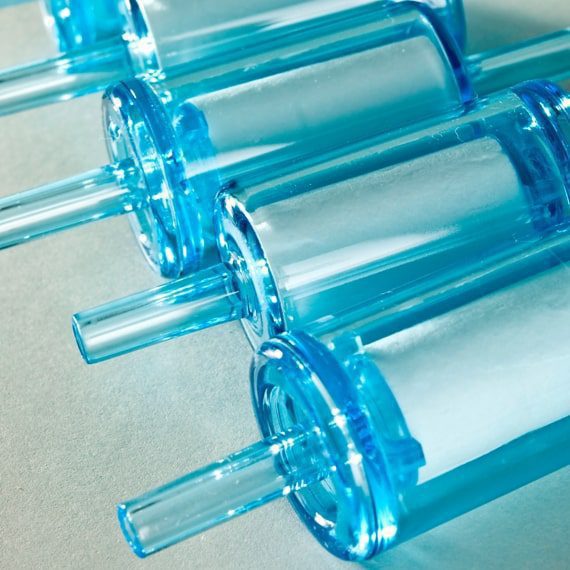

What is a borosilicate glass microfiber element?

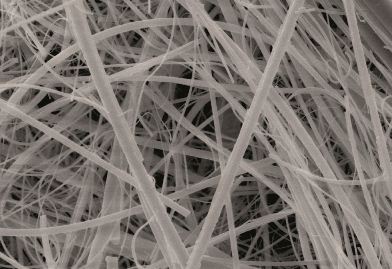

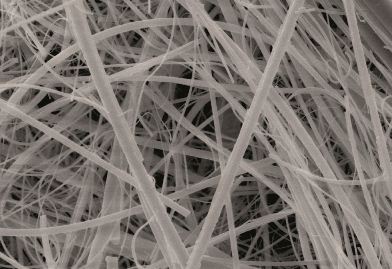

Borosilicate glass is known and used quite extensively throughout the glass industry, specifically for laboratory glassware, being made from Boron and Silica, and the microfibers are what they say they are, very fine fibre of specific diameters and lengths blended and formed in a specific manor to produce a matrix with certain sizes of free area dependant on grade.

Why are borosilicate glass microfibre elements so good for particulate and coalescing filtration?

The fibres are selected, treated and formed in such a way that they form a very tight labyrinth that has an enormous amount of free area, the labyrinth causes the particles or aerosols to constantly change direction and as they do their speed decreases until they are caught by the glass fibres.

How do they get caught?

They either come to a gap too small for them to travel through or they get caught on the fibres, which because of the way they are treated have a surface that grabs small particles and aerosols. This is accentuated by the fact that the fibres also have a static charge, even though they are normally coated with a binder of some sort. At this stage coalescing and particle filters behave differently.

With the particle filters the particles are held firm and as more get attached to the same spot; the tighter they are held. Due to the fact there is so much free area within the labyrinth an enormous amount of dirt is held in comparison to the size of the filter element. In fact far more dirt is held than any other type of element, before the element becomes too blocked or blinded and needs changing.

A coalescing element is constructed with a fine layer of borosilicate glass micro fibres which is described above, with a coarser layer of borosilicate glass microfibers formed on the outside of the fine layer. As the aerosol is captured in the fine layer, gradually they start to pool together and as the droplets form they start to move partly by capillary action and partly from the fluid flow through the element. As they move they gather more of the aerosol making the droplets larger, but in the fine layer their growth is restricted, until they move into the coarse layer, where the droplets can really start to form. These droplets gradually move and grow all the time until they reach the outside of the element, where they can clearly be seen to form and run down the side of the element eventually dropping off the end.

No other element works as efficiently or gathers as many particles or as much aerosol as a borosilicate glass microfiber element.

You can leave a comment below or contact us by calling +44 (0)1634 724224, use the form on the right or send us an email to [email protected]