Dead Volume Often Overlooked in Sample Systems

Often the most overlooked area when designing a sample conditioning system is the dead volume, or dead space, in the filter housing. Dead volumes are parts of the sample system where fluid can become stuck and won’t be able to move along with the main flow of the sample.

What is best size filter housing for a sample system?

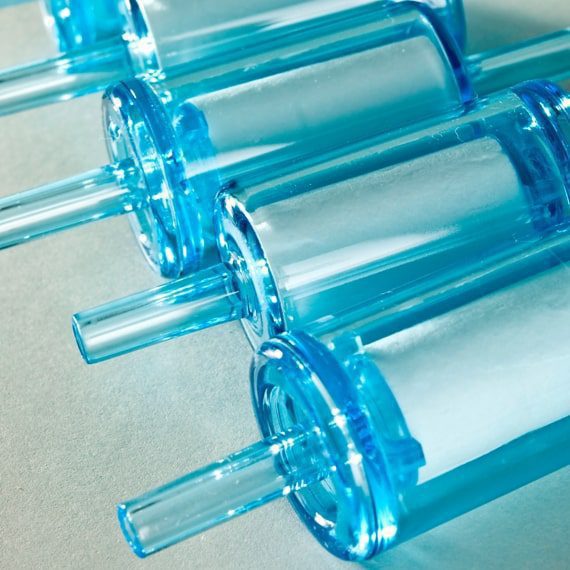

If a large filter housing is used in the in the sample conditioning system the service times will be extended but the response time will be increased. Our filter housings are carefully designed to eliminate dead volume around the filter elements and in the base of the bowl. Selecting the correct filter housing should done with consideration of the compromise between response time and service life.

Small internal volume gives a faster response time

By selecting the smallest stainless steel filter, such as a SS117 series, the total volume is greatly reduced and the response time increased giving a faster sample transit time.

The use of Fast Loop Filters (Bypass Filters) can often help to minimise the dead volume of a sample system and we have talked about these on the blog previously.